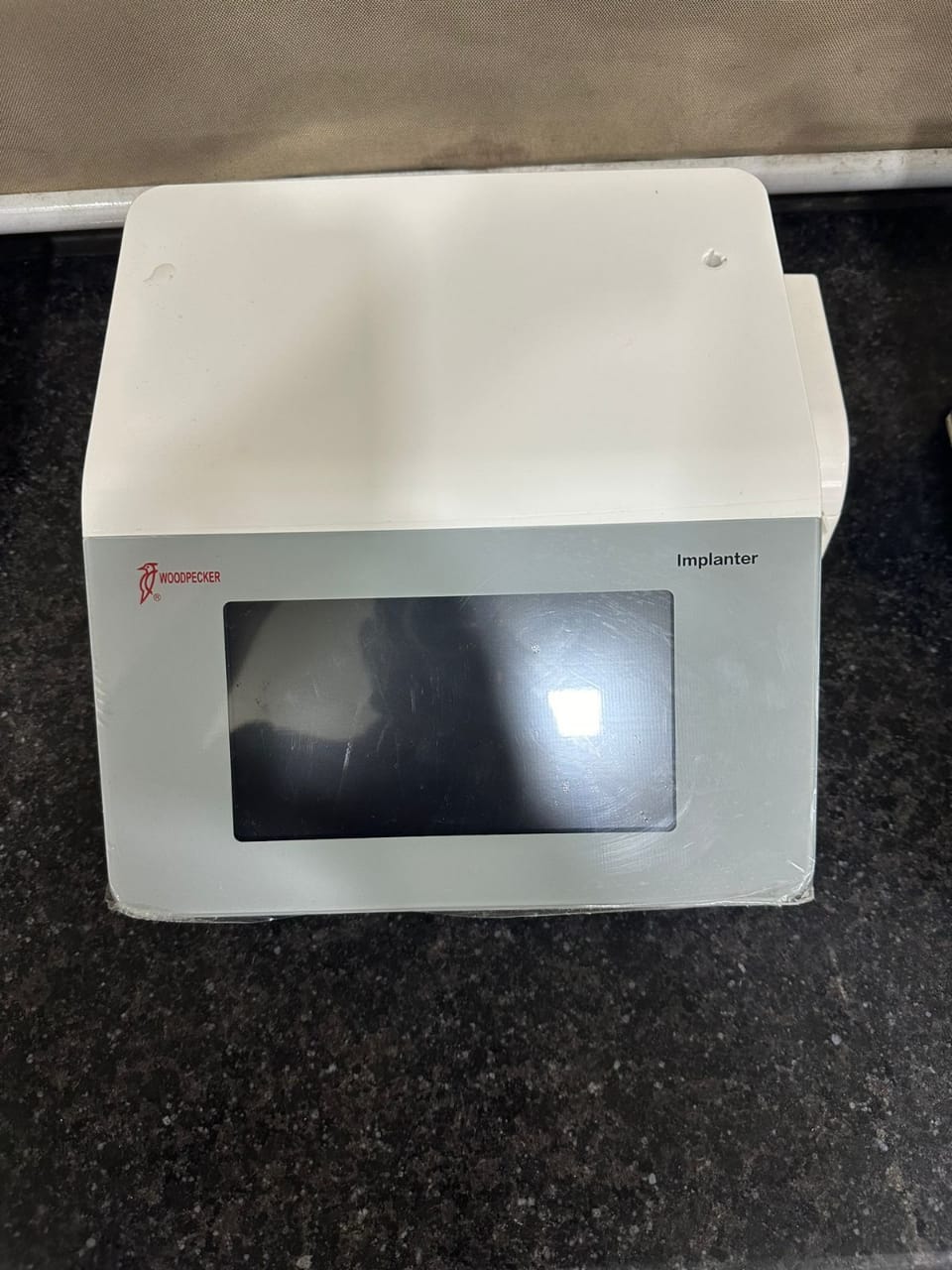

Dental Implant Welders: Pioneering Precision in Dental Restoration

Dental implant welders are revolutionizing dental restoration by providing a highly precise and reliable method for creating and customizing implant components. These advanced machines play a critical role in welding metal parts used in dental implants, ensuring that every piece fits perfectly and functions seamlessly. By utilizing high-tech welding techniques, dental implant welders significantly enhance the strength and durability of implant frameworks, which is essential for successful integration with the jawbone and long-term stability.

Customization for Enhanced Comfort and Aesthetics

One of the standout advantages of dental implant welders is their ability to produce custom-fit implants and prosthetics tailored to the specific needs of each patient. The precision offered by these machines allows for the creation of dental restorations that improve both comfort and aesthetic appeal. This level of customization ensures that patients receive implants that not only function optimally but also blend naturally with their existing teeth, enhancing the overall patient experience.

Streamlining Production for Superior Patient Care

In addition to improving the quality of dental restorations, dental implant welders streamline the manufacturing process, reducing both production time and costs. Despite the efficiency gains, these machines maintain the highest standards of quality, contributing to a higher overall success rate of dental implants. The incorporation of dental implant welders into modern dental practices supports more efficient, patient-centered care, ultimately advancing the field of dental restoration and improving patient outcomes.